This post is also available in:

עברית (Hebrew)

עברית (Hebrew)

Handling irregular, delicate, or heavy objects remains a persistent challenge for both industrial automation and frontline operations. Conventional grippers rely on rigid claws or suction, which can damage sensitive items or fail to secure objects with unusual shapes. In constrained spaces—such as cluttered warehouses, collapsed structures, or tight storage bays—reaching and gripping becomes even more difficult.

A new robotic design from MIT and Stanford proposes a different approach. Drawing inspiration from the way vines wrap themselves around nearby supports, researchers developed a soft, inflatable gripper that grows outward from a compact chamber, coils around a target, and then retracts to lift it. Instead of relying on forceful clamping, the system forms a sling-like cradle tailored to the object’s shape, allowing it to raise items as varied as a glass vase, a watermelon, or even a person.

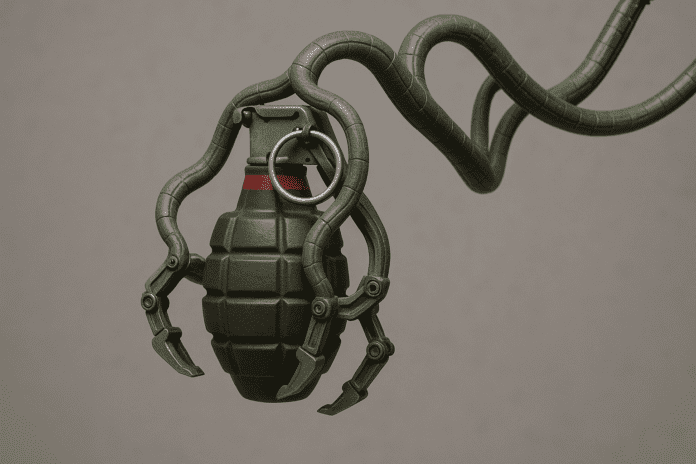

For defense and homeland-security missions, such a mechanism could provide a safer option for handling unstable or dangerous materials. Robots used in explosive ordnance disposal, tunnel inspection, or disaster response often need to retrieve sensitive or irregular objects without applying damaging pressure. A soft, shape-conforming gripper could reduce breakage and improve operator safety in environments where traditional manipulators are too rigid to be reliable.

According to TechXplore, the system works through inflatable tubes that invert as they extend, much like fabric turning inside out. When deployed, two or more of these “vines” can navigate through narrow gaps or around obstacles, then curl beneath and around a load. Once both ends return to their starting points, a locking mechanism turns the open loop into a closed one. A winch then reels the tubes back in, lifting the object in a controlled, even manner. This approach avoids sharp pressure points and distributes weight across the entire vine surface.

Researchers built both a small-scale version that mounts to a robotic arm and a larger setup capable of lifting a person from a bed—demonstrating potential in both industrial logistics and patient assistance. The gripper also proved capable of pushing through clutter to reach hidden items, something rigid arms struggle to do without knocking objects aside.

While initially motivated by healthcare challenges, the underlying technology offers a flexible, low-damage gripping method suitable for a range of sectors, from agriculture to heavy industry and field robotics.

The research was published here.