This post is also available in:

עברית (Hebrew)

עברית (Hebrew)

Developing vehicles that can travel at hypersonic speeds—Mach 5 and above—poses extreme engineering challenges. At such velocities, airframes are subjected to intense vibration, aerodynamic heating, and structural stress. Even minor weaknesses can lead to catastrophic failure. Verifying that materials and components can survive these forces is a critical step before any flight test.

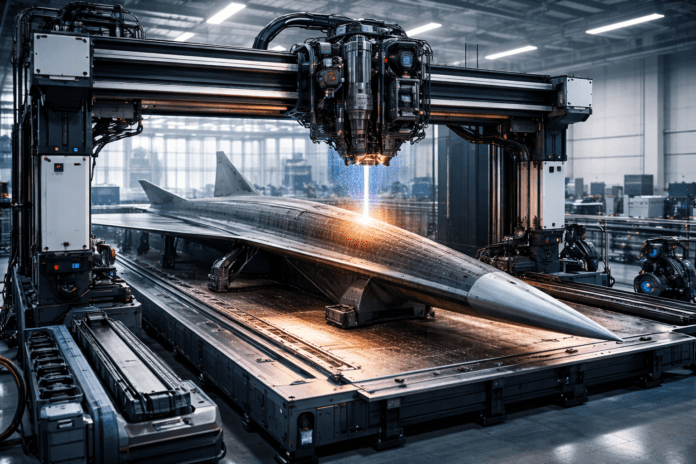

A new hypersonic demonstrator has now cleared a major milestone in that process. The DART AE (by Hypersonix), a single-use technology vehicle designed to reach speeds of up to Mach 7, has successfully completed vibration testing to validate its structural integrity. These ground-based trials simulate the mechanical loads experienced during launch and sustained high-speed flight, ensuring that the airframe and internal systems can withstand real-world stresses.

According to Interesting Engineering, what sets this vehicle apart is its manufacturing approach. It is described as the world’s first hypersonic platform with an entirely 3D-printed airframe built from high-temperature alloys. Additive manufacturing enables complex geometries that would be difficult or impossible to produce using traditional methods, while also reducing part counts and potentially shortening production timelines. The vehicle measures roughly three meters in length, weighs about 300 kilograms, and is designed for a range of up to 1,000 kilometers.

Propulsion is provided by a hydrogen-fueled scramjet engine. Scramjets operate by compressing incoming air at supersonic speeds without moving parts, making them suitable for sustained hypersonic flight. Hydrogen fuel is highlighted for its high energy output and clean-burning properties, supporting both thrust performance and thermal management.

From a defense perspective, hypersonic technologies have attracted significant attention due to their speed and maneuverability. Vehicles traveling at Mach 7 can cover long distances in minutes, compressing decision timelines and challenging existing air and missile defense systems. Demonstrators such as this one contribute to understanding materials, propulsion, and manufacturing techniques required for future high-speed platforms.

Although details of upcoming flight tests have not been disclosed, completing vibration trials marks a key step toward integration and pre-flight preparation. Beyond performance, the use of full-airframe additive manufacturing signals a shift in how advanced aerospace vehicles may be produced. If validated in flight, the combination of scramjet propulsion and 3D-printed high-temperature structures could influence the next generation of hypersonic systems, both civilian and military.