This post is also available in:

עברית (Hebrew)

עברית (Hebrew)

Rapid deployment is a recurring challenge in emergency response and field operations. Whether setting up medical facilities after a natural disaster or assembling equipment in remote locations, time, manpower, and transport volume are often in short supply. Many deployable structures exist, but they are usually limited to simple shapes or require multiple steps, tools, or skilled assembly to reach their final form.

Researchers at MIT have developed a new design method that simplifies this process dramatically. Their approach allows complex three-dimensional structures to be fabricated in a flat state and then deployed into their full shape with a single pull of a string. Once the tension is released, the structure quickly collapses back into its flat configuration, making it reusable and easy to transport.

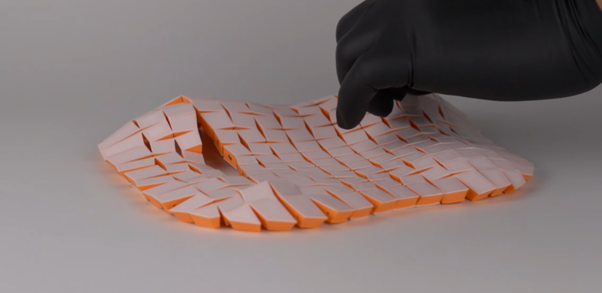

The technique starts with a user-defined 3D shape. An algorithm then converts that geometry into a flat layout made of interconnected tiles joined by rotating hinges. Drawing inspiration from kirigami, the system encodes the desired 3D form into an auxetic pattern—one that expands or contracts in a controlled way. The key innovation lies in how the actuation is handled: the algorithm calculates an optimized path for a single string that, when tightened, lifts specific points and guides the entire structure into its final shape with minimal friction.

Because the deployment relies on just one motion, the system avoids the complexity of motors, multiple cables, or sequential assembly steps. The method is also fabrication-agnostic. The flat tiles can be produced using 3D printing, CNC milling, molding, or other manufacturing techniques, depending on the application. Hinges can be made flexible while the rest of the structure remains rigid, enabling smooth transformation.

For defense and homeland security uses, the concept has clear relevance; rapidly deployable structures could support temporary field hospitals, command posts, shelters, or equipment enclosures in disaster zones or forward operating areas. Flat-packed designs reduce logistical burden, while fast, low-effort deployment helps operations begin sooner with fewer personnel. The reversibility of the mechanism also supports redeployment or relocation as conditions change.

According to TechXplore, the researchers demonstrated the method across a wide range of scales, from small medical devices such as splints and posture supports to human-sized furniture and portable shelter-like forms. Because the underlying algorithm is scale independent, the same approach could be applied to miniature deployables or large architectural frames.

Looking ahead, the team plans to explore self-deploying versions and address engineering considerations such as hinge strength and cable thickness for larger installations. The work shows how careful algorithmic design can turn a simple physical action into a reliable way to deploy complex structures when speed and simplicity matter most.

The research was published here.