This post is also available in:

עברית (Hebrew)

עברית (Hebrew)

Researchers from North Carolina State University created a material that is both hard and stretchy –glassy gels contain more than 50% liquid and are totally changing the game of flexible electronics and wearable devices.

“Creating glassy gels is a simple process that can be done by curing it in any type of mold or by 3D printing it,” stated co-author Michael Dickey in a press release.

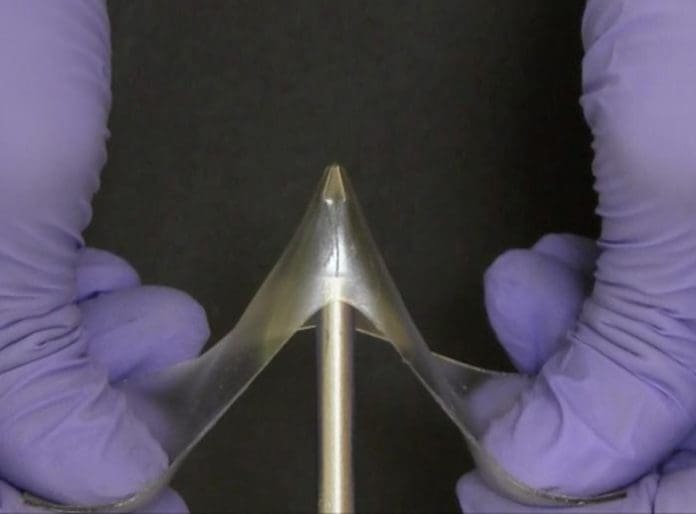

According to Interesting Engineering, gels and glassy polymers have typically been seen as completely different. While gels (like contact lenses) are soft and contain a lot of liquid, water bottles and airplane windows are made of glassy polymers that are hard and brittle. The revolutionary glassy gels combine the best of both materials – the material is incredibly strong and hard, but can stretch up to five times its original length. “What’s more, once the material has been stretched, you can get it to return to its original shape by applying heat. In addition, the surface of the glassy gels is highly adhesive, which is unusual for hard materials,” explained Dickey.

The researchers were able to create the material using a unique combination of ingredients, which they put into a mold and cured under UV light.

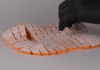

Interestingly, glassy gels are over 50% liquid. This liquid component can contain dissolved salts or other ionic compounds, which act like the charged particles needed for electricity conduction. Their conductivity makes them ideal for new types of flexible electronics. Plastics, however, lack these freely moving charged particles within their structure, which makes them not ideal for devices.

During material testing, the researchers demonstrated one of the more remarkable property of glassy gels, which is their resistance to drying despite containing 50-60% liquid.

The researchers concluded that they are optimistic that these materials could be extremely useful for many uses and applications.