This post is also available in:

עברית (Hebrew)

עברית (Hebrew)

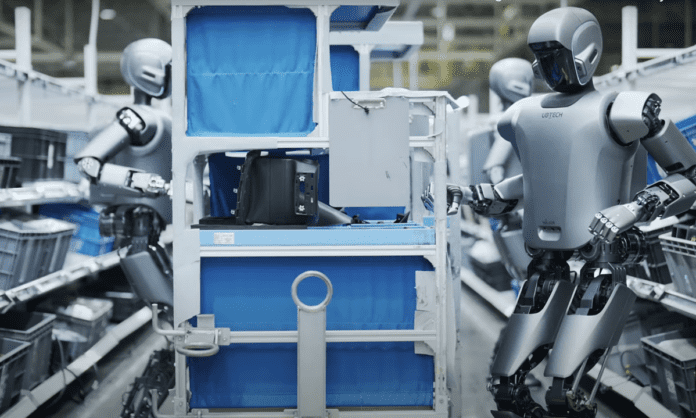

Chinese robotics company UBTech has apparently achieved a significant milestone in the field of humanoid robotics with the successful deployment of multiple humanoid robots working collaboratively in industrial environments. This breakthrough, demonstrated at Zeekr’s 5G Intelligent Factory in China, marks the world’s first instance of humanoid robots working in sync across various tasks and scenarios on a production line.

At the core of this achievement is UBTech’s innovative BrainNet framework, which enables robots to cooperate and execute complex tasks seamlessly. A team of Walker S1 humanoid robots, connected through the BrainNet system, showcased their ability to work together in an environment requiring precision, adaptability, and advanced coordination. This collaboration, powered by AI-driven swarm intelligence, sets a new benchmark in robotics, demonstrating how humanoid robots can cooperate to perform jobs previously reserved for human workers.

The key to this collaboration is UBTech’s “super brain” and “sub-brain” model, which links cloud-device nodes with skill nodes, creating an intelligent network capable of decision-making and task coordination. The system allows robots to autonomously learn, adapt, and make real-time decisions, significantly enhancing production-line efficiency. The BrainNet framework combines multi-robot control with cross-field perception, enabling the robots to perform tasks such as sorting, handling, and assembly with exceptional precision.

UBTech’s humanoid robots also employ multimodal reasoning models, built on the Transformer model, to process large-scale industrial data and improve decision-making accuracy. The robots’ ability to handle dynamic targets, adjust force and position during collaborative handling, and ensure the safety of deformable materials during assembly, all with high precision, demonstrates the advanced capabilities of this new system.

This development is part of UBTech’s broader vision to mass-produce Walker S humanoid robots, targeting up to 1,000 units by the end of the year. As the company continues to push the boundaries of AI and robotics in industrial applications, it is paving the way for the future of intelligent, autonomous manufacturing.