This post is also available in:

עברית (Hebrew)

עברית (Hebrew)

Typically, underwater solar cells are affected by biofouling: the accumulation of marine organisms such as algae and barnacles on submerged surfaces, which typically reduces the efficiency of underwater solar cells and increases maintenance costs. Researchers from the Technical University of Denmark, funded by the US Navy, have developed an innovative coating for underwater solar cells that ensures they remain efficient underwater by addressing the challenge of biofouling.

The coating’s design involves nano-sized pigments like cuprous oxide (Cu2O) and zinc oxide (ZnO) dispersed in the binder. When exposed to seawater, these pigments dissolve to form a porous layer. This porous structure allows seawater to seep into the coating, facilitating the release of biocidal compounds that combat biofouling. The binder matrix also reacts with seawater ions to regulate the polishing rate, ensuring that the coating maintains its anti-fouling properties while continuously polishing itself.

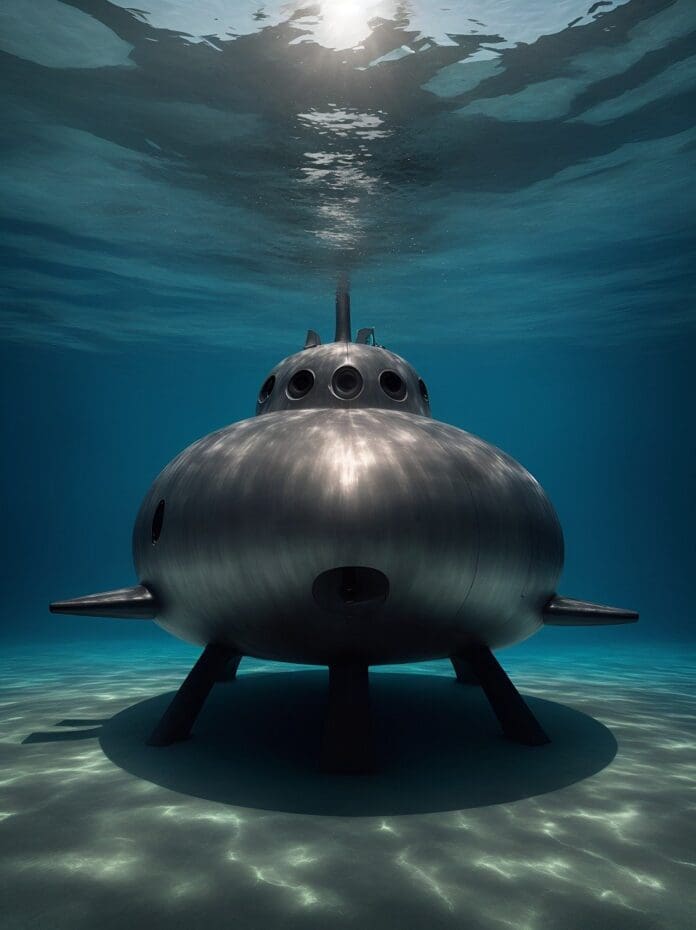

Solar panels are essential for extended missions of Unmanned Underwater Vehicles (UUVs) and solar-powered Autonomous Underwater Vehicles (AUVs). However, biofouling reduces the optical efficiency of these panels over time, impairing the vehicles’ maneuverability and performance. Existing antifouling coatings, such as silicon-based fouling release coatings and cuprous oxide, either require mechanical cleaning or obstruct visible light, limiting their effectiveness for these applications.

According to Interesting Engineering, the researchers aimed to create a self-polishing antifouling coating that maintains over 80 percent light transmission and 90 percent solar power generation for at least three months without mechanical intervention. Their innovative coating achieved these goals by utilizing the combined effects of materials.

In testing, the coated panels, submerged in Hundested Harbor, Denmark, for two and a half months, exhibited significant resistance to fouling. The coating was polished at a rate of 1.4 micrometers per day and maintained nearly 100 percent solar power efficiency over 13 weeks in Florida. This represents a significant advancement in developing clear coatings that can resist fouling while maintaining optical clarity for underwater cameras and sensors.

This research, detailed in the journal Progress in Organic Coatings, marks a major step forward in ensuring that underwater solar cells and sensors remain efficient and reliable despite prolonged exposure to marine environments