This post is also available in:

עברית (Hebrew)

עברית (Hebrew)

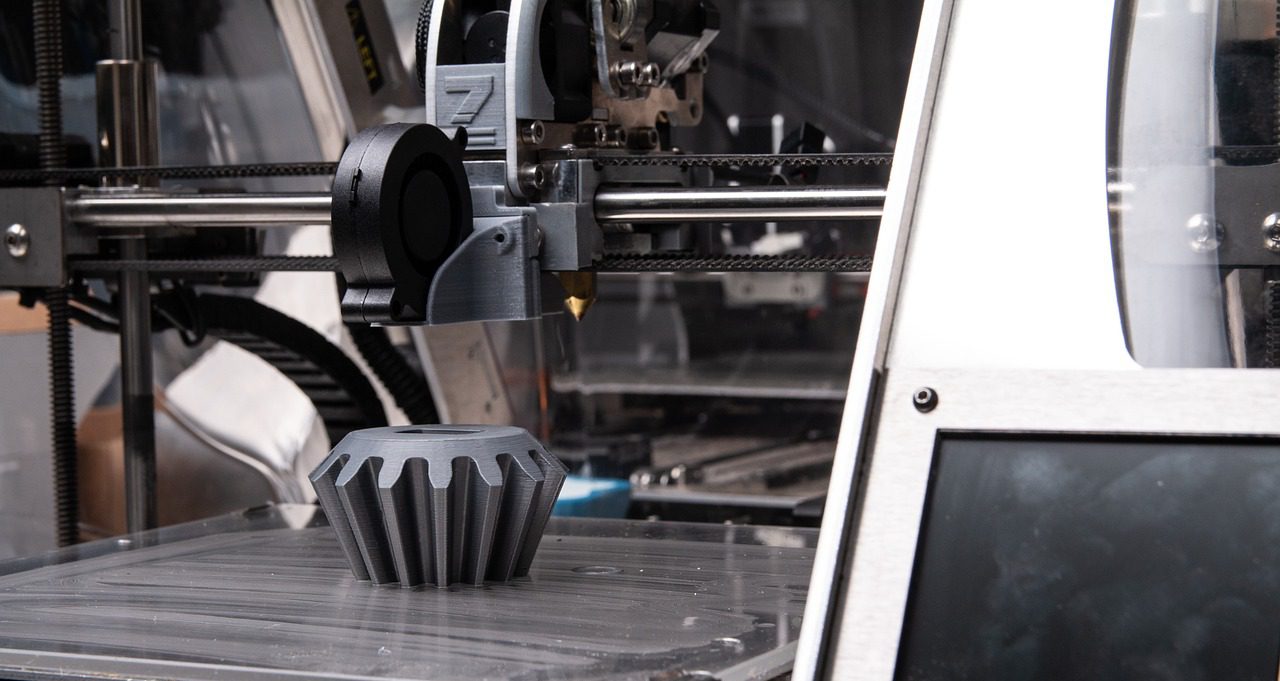

A new research effort is offering a clearer picture of how lightweight 3D-printed components perform under stress, with the potential to improve reliability and efficiency across several industries. The work focuses on enhancing strength prediction methods for parts made using additive manufacturing (AM), particularly those with complex internal geometries designed to reduce material use without compromising performance.

Conducted at the University of Maine’s Advanced Structures and Composites Center, the study introduces a new modeling approach that blends computational simulations with physical testing. The researchers focused specifically on gyroid infill—a repeating, lattice-like internal structure frequently used in 3D printing due to its ability to distribute stress efficiently and maintain stability while significantly reducing weight.

To assess how this infill pattern responds to different types of mechanical stress, the team performed finite element analysis (FEA) simulations and then tested physical prototypes under compression and shear. The results confirmed that their predictive models closely aligned with real-world performance, allowing for more accurate forecasts of structural behavior, according to Interesting Engineering.

Unlike conventional methods that often fall short in evaluating the mechanical performance of intricate infill designs, the researchers’ approach provides semi-empirical equations that can be used directly in the design process or integrated into optimization tools. This allows engineers to make more informed decisions about material selection and structural layout early in the development process.

This advancement is particularly relevant to sectors such as aerospace, automotive, defense, and medical devices, where high strength-to-weight ratios are critical. With more accurate data on how gyroid-infilled parts behave under load, designers can reduce unnecessary material use while maintaining or even improving mechanical performance.

The researchers also note that their methodology is not limited to gyroid structures. It can be adapted for analyzing other infill patterns commonly used in additive manufacturing, opening up broader applications for lightweight structural design.

The study’s findings, recently published in Progress in Additive Manufacturing, mark a significant step toward more efficient and reliable 3D-printed components, providing engineers with tools to better predict and optimize performance from the design stage forward.