This post is also available in:

עברית (Hebrew)

עברית (Hebrew)

Diamonds, the most precious of stones, have far more uses than you might think, and the Israeli company Ray Techniques is giving them away for free for testing, but not for jewelry purposes.

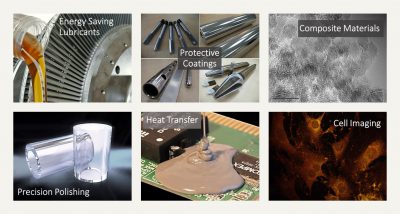

Meet nanodiamonds – diamond particles 20,000 times smaller than the thickness of a human hair (less than a hundredth of a micron) that have a myriad of applications: a range of medical innovations including cancer treatment, the transition to safe nuclear energy through slow neutron reflectors, and of course the improvement of many materials and processes – polymers, lubricants, coatings, catalysts, materials for 3D printing, thermal interfaces and much more.

Ray Techniques is revolutionizing nanodiamond technology because it is the only company in the world to produce high-quality nanodiamonds by laser processing a mixture of soot and wax using a patented process. This technique is much safer and more efficient than the current method of detonating TNT and RDX explosives in big metal chambers.

Another Ray Techniques innovation is the know-how of dispersing nanoparticles in various materials. At present, the problem of aggregation significantly limits the possibilities for industrial implementation of nanodiamonds. The company has solved this problem and produces ready-to-use additives in the form of diamond nanofluids based on various solvents, oils, and resins. These additives improve the performance of materials, speed up production processes, and reduce costs. For example, adding nanodiamonds to motor oils at a final concentration of just three-hundredths of a percent reduces friction, wear, noise, and pollution, doubles engine life, and leads to fuel savings of 2 to 7 percent.

The innovative potential of nanodiamonds is huge; let’s take wind energy as an example. The use of nanodiamonds in the manufacturing and operation of wind turbines is expected to double the output of wind farms and cut the cost of electricity by half. The addition of nanodiamonds to blade polymers is expected to increase the strength and durability of the materials, making it possible to lengthen the blades and thus increase the power output; at the same time, the use of nanodiamonds in the lubrication of gears and bearings will reduce energy losses due to friction, double the life of mechanisms and reduce operating and capital costs.

The need to standardize nanodiamonds is an important issue in the global nanodiamond market that is expected to be resolved this year: the company is participating in an international committee to establish a standard for nanodiamonds, with the aim of facilitating the introduction of nanodiamonds into industrial polymer production.

Ray Techniques believes that the use of nanodiamonds in a wide range of industrial, energy, medical, and science applications will contribute to a greener, better, and more efficient future. The company is therefore making nanodiamond samples available free of charge to researchers and potential customers around the world.

Ray Techniques is a graduate of the INNOFENSE Innovation Center operated by iHLS in collaboration with IMoD. A unique accelerator program that removes barriers to entry into the technology ecosystem, transforming start-ups into mature, leading companies and connecting them with relevant investors, with the aim of strengthening the links between the civil and defense markets through the co-development of technologies, thereby promoting and improving their integration in both markets.

For further information please contact [email protected]