This post is also available in:

עברית (Hebrew)

עברית (Hebrew)

Peacekeeping missions often take place at remote locations, requiring the army to have a large supply of spare parts on site to keep everything running. In many cases it is simply too expensive to shut down a technical system until a new part has been printed. In these cases, parts must be ‘on the shelf’ so that they can be replaced immediately. Yet the army’s systems have many thousands of types of spare parts.

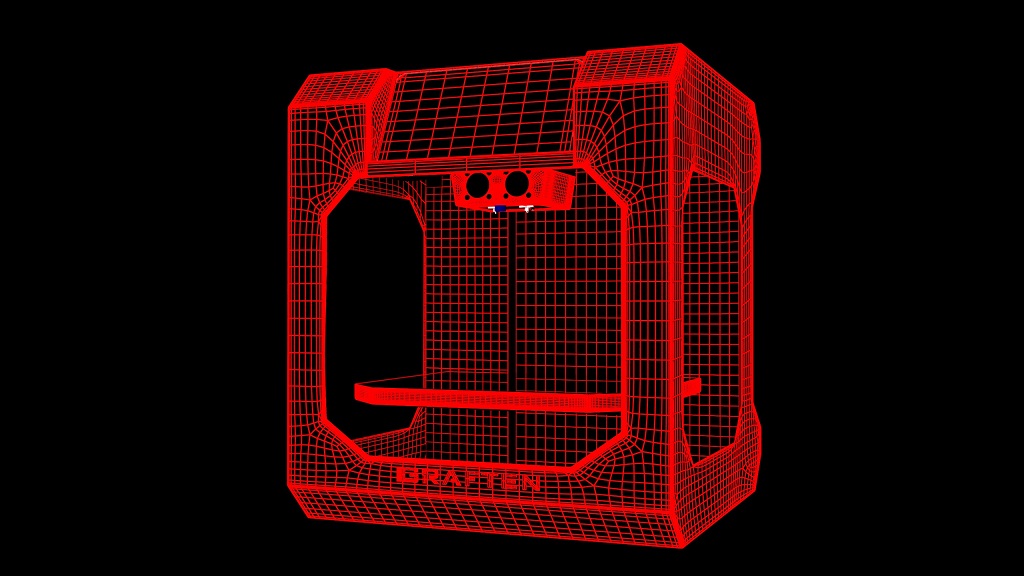

The 3-D printing technology has been developing rapidly, enabling on-demand printing of spare parts via local 3-D printing hubs. This theoretically eliminates the need for firms to keep spare parts inventory, even though such printed parts may not be as reliable as regular spare parts, according to a new research published on ssrn.com.

Taking a 3-D printer on a mission to print parts can save hundreds of thousands of euros and, at the same time, reduce the downtime of defense equipment. The savings on operational costs sometimes total more than half.

Dutch researcher Bram Westerweel claims that the technology can also be applied to industries with remote locations, such as the offshore industry. The research took a broader perspective of the possibilities of including 3-D printers in the logistics chain of supplying spare parts.

Based on his research, Westerweel expects that a total of 10-20 percent of the components of the armed forces can be made by additive manufacturing, also known as 3-D printing. The total savings by 3-D printing on relatively large peacekeeping missions like the ones in Mali and Sudan, could then run up to hundreds of thousands. The Dutch army is already experimenting with such a printer in Mali.

The business model offered is based on equipment builders shifting from selling and shipping physical parts, to selling licenses for digital design files that allow others, anywhere in the world, to print parts locally. Such licensing of intellectual property also allows the supply chain to completely decentralize, with traditional mass-manufacturing facilities being replaced by local printing hubs that can simply download component designs from central servers, according to phys.org.