This post is also available in:

עברית (Hebrew)

עברית (Hebrew)

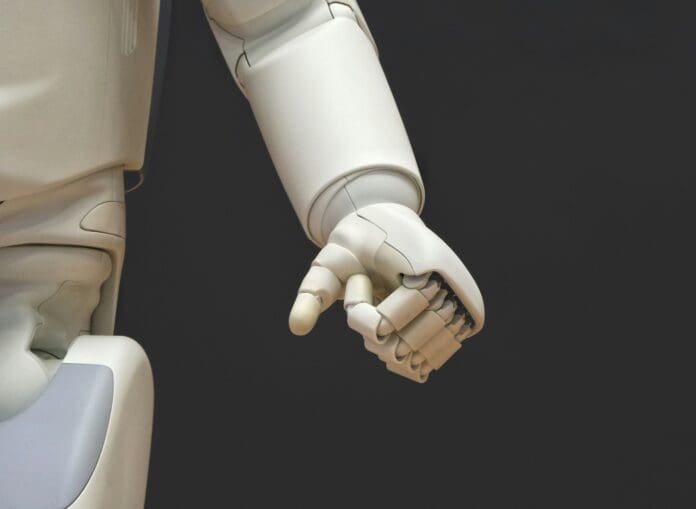

Researchers at Universidad Carlos III de Madrid (UC3M) have developed a cutting-edge soft joint model that promises to significantly enhance the versatility, robustness, and safety of robots. The innovative joint design features an asymmetrical triangular structure with an ultra-thin central column, enabling a range of benefits in robotic applications.

This soft joint allows robots to achieve greater bending angles with minimal force, offering enhanced movement flexibility and adaptability. By incorporating asymmetry into its structure, the joint automatically locks when it reaches its design limits, preventing material damage and ensuring safe operation. This feature makes the joint particularly effective in protecting robotic systems from potential mechanical failure during operations.

One of the key advantages of the soft joint is its ability to absorb impacts, improving the safety of robots when interacting with humans or navigating unpredictable environments. The researchers also explain that the flexible material used in the joint enhances its shock-absorbing capabilities, making it ideal for delicate or confined spaces, where precision and adaptability are critical.

Moreover, the joint’s design is not only robust but also versatile. It can function independently or be integrated with other joint modules to form a highly functional robotic handling system, according to the researchers. This adaptability opens up new possibilities for its use in a variety of industries, including manufacturing, healthcare, and logistics.

Another major advantage of this soft joint is its ease of production. The joint can be manufactured using standard 3D printing techniques and elastic materials, allowing for rapid and cost-effective production without significant investment. This makes it an attractive option for companies looking to develop or enhance robotic systems without high upfront costs.

Currently, the team at UC3M RoboticsLab is working on a robotic claw that incorporates this patented joint design, enabling highly dexterous object manipulation. This breakthrough has the potential to revolutionize robotic capabilities, providing safer, more adaptable, and more cost-effective solutions for various industries.