This post is also available in:

עברית (Hebrew)

עברית (Hebrew)

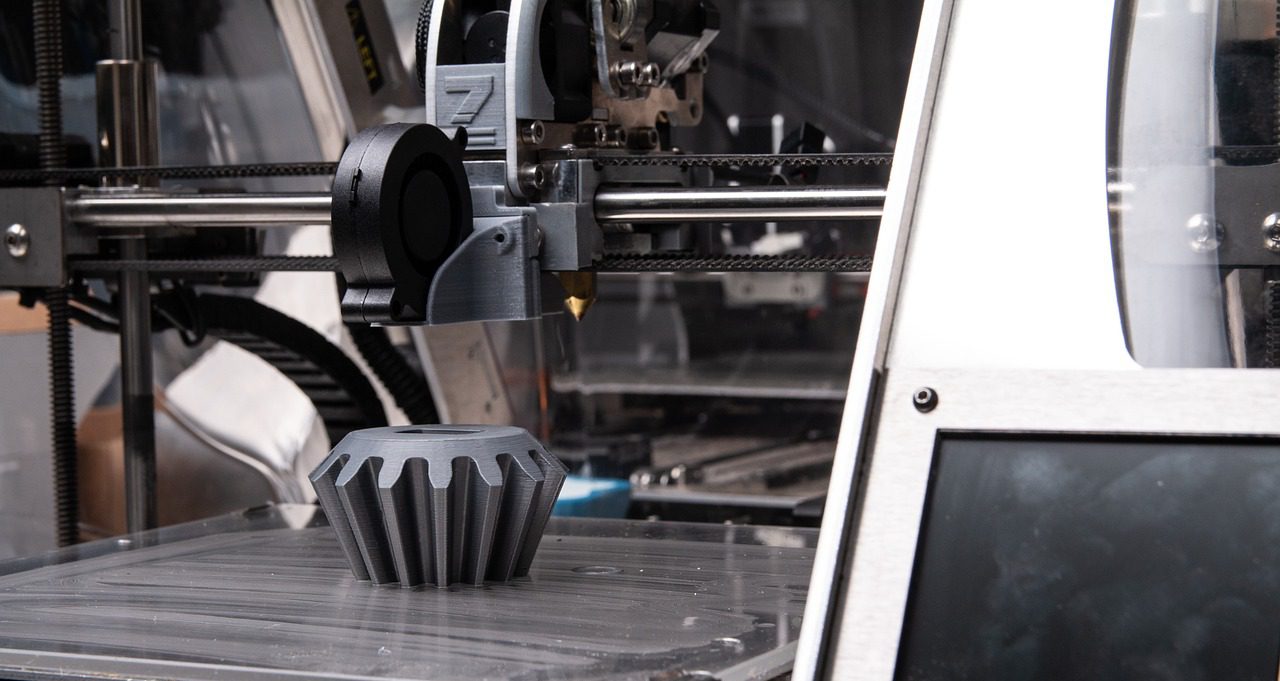

3D printing concrete has recently become more popular. Like regular 3D printers, concrete printers work by building a structure layer by layer based on a design made on a computer program. This time, however, a cement-like substance is used instead of plastic filament. In contrast with traditional construction, 3D printing concrete hastens the construction process, adjusts it to the architect’s vision, reduces costs of labor, and minimizes waste.

Still, the available printable materials currently are limited, and their sustainability and durability persist to be an issue. Recently, a team of Engineers from the University of Virginia School of Engineering and Applied Science managed to incorporate tree-pulp-derived cellulose nanofibrils into 3D-print concrete, possibly making it more durable and eco-friendly.

According to Innovation News Network, the team explains that creating the perfect mixture was difficult, as it must have contradicting qualities: “it has to flow well for smooth fabrication but harden into a stable material with critical properties, such as good mechanical strength, interlayer bonding, and low thermal conductivity.” This is why the team decided to use cellulose nanofibrils (CNF), ultra-fine fibers made from cellulose, the primary structural component of plant cell walls. In addition to being sustainable, this material has strong potential to improve both the flow and the strength of the concrete it produces.

Prior to the study, knowledge on CNF’s influence on 3D printable materials was limited. The team had to go through a lot of trial and error, but eventually discovered that a minimum of 0.3% CNF is required to considerably improve the flow of the concrete mixture. Further, microscopic examination of the hardened samples revealed improved material bonding and enhanced structural integrity. Testing displayed that 3D-printed components enhanced with CNF showed better resistance when pulled, bent, or compressed.

This research is a significant and important step for the sustainability of the construction industry.

The team’s study was published on Science Direct