This post is also available in:

עברית (Hebrew)

עברית (Hebrew)

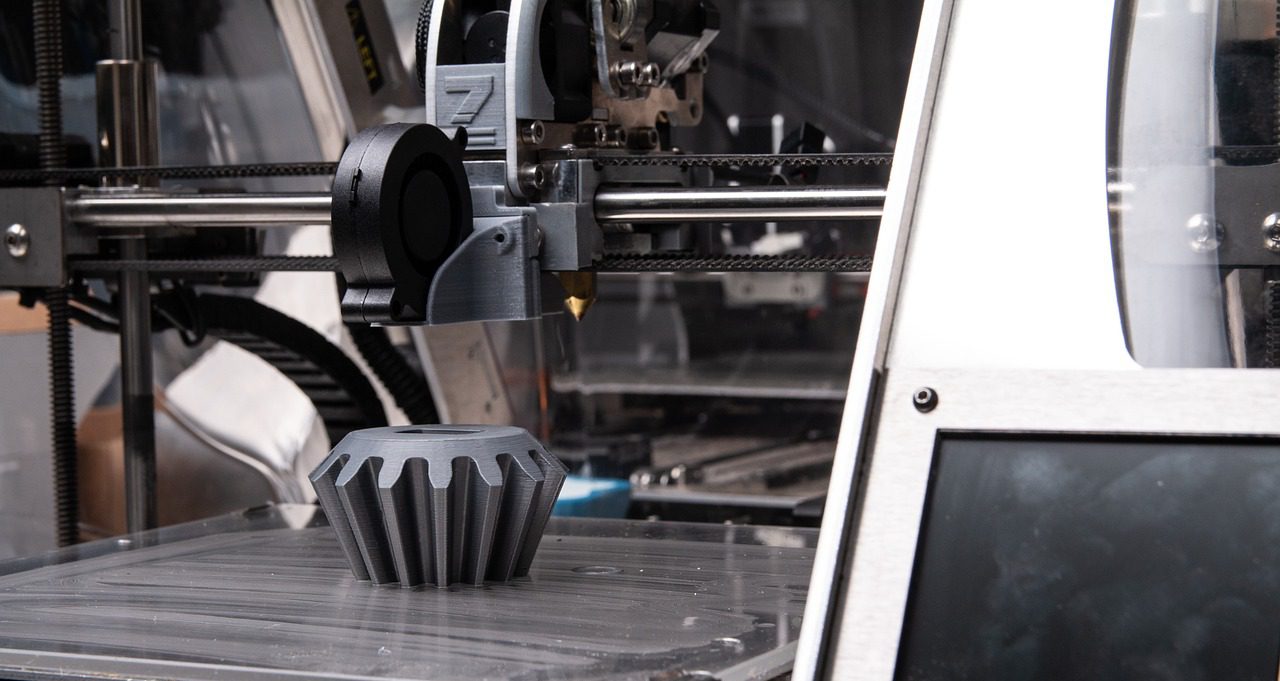

Propulsion manufacturer Ursa Major announced its innovative 3D printing process for solid rocket parts, which is expected to make production cheaper and faster. The process is called “Lynx” and can be used for design and final manufacture. The company will begin by 3D printing motor cases and subcomponents for smaller systems, but believes it could be used for many other rocket parts in the future.

Founder and CEO of Ursa Major Joe Laurienti stated that the solid rocket motor production process will transform due to the increasing use of additive manufacturing, leading to an increase in the nation’s ability to replenish its depleted stocks of weapons like the “Javelin” and the “Stinger.”

According to Interesting Engineering, Ursa Major began developing the “Lynx” process by looking at the needs of the industry and seeing where there are bottlenecks that need fixing. The Lynx process lets a company be very flexible in its production needs, switching from manufacturing parts for a certain rocket one day, and another rocket the next without hindrance or delays.

Laurienti explains that the 3D-printed design by Ursa Major will enable specific components to be fabricated together as a single piece, unlike the conventional approach, where different parts are made separately and then assembled- resulting in fewer parts being needed, greater automation, and reduction in overall costs.

The company claims it can 3D print up to 50 small engine cases within three days, in contrast to traditional manufacturing processes that can take months. Ursa Major also developed multiple metallic alloys that are suitable for 3D printing.

The company reportedly plans on announcing the first system using “Lynx” by the end of this year, as well as another one early next year, and by the end of 2024, it will use “Lynx” to manufacture parts for up to four systems.