This post is also available in:

עברית (Hebrew)

עברית (Hebrew)

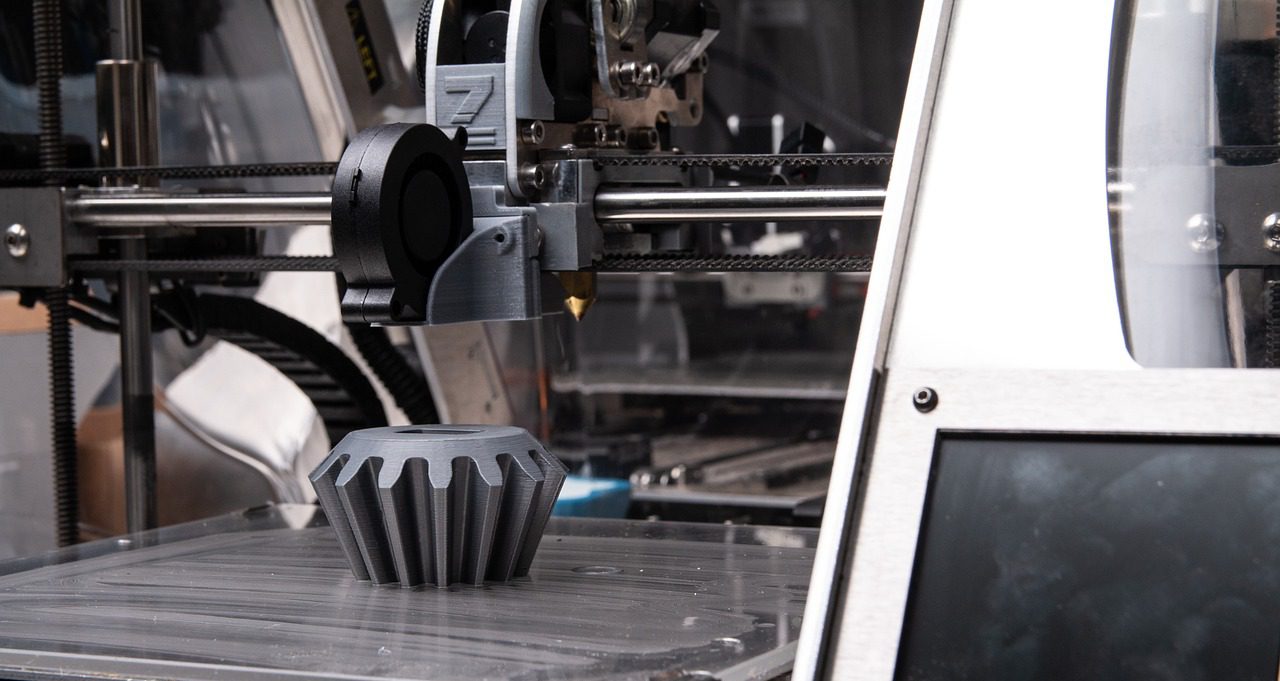

According to a recent report by the US Army, a certain new and innovative type of technology will most definitely help the DoD in numerous ways. This secret weapon the US Army spoke about is Micro-precision 3D printing.

Micro-precision 3D printing combines ultra-high resolution, accuracy, and precision allowing for more intricate, exact, and replicable parts. Micro-3D printing, an additive manufacturing technology that enables the miniaturization of parts and components, could be applied for military purposes.

These include enhancing capabilities to existing systems, volume optimization to reduce the size and weight of equipment troops must carry, and allowing for new technology solutions that were previously unavailable, said James Zunino III, senior scientific technical manager for munitions at the US Army Combat Capabilities Development Command’s advanced materials and manufacturing division.

Boston Micro Fabrication is conducting pioneering work with micro-3D printing techniques to meet the growing demand, such as in the field of miniaturizing lenses or sensors. Traditional manufacturing techniques that have historically been used to make the parts don’t scale well and have other limitations. To address this, the company developed a process it calls projection micro stereolithography. According to nationaldefensemagazine.org, the technique allows for the rapid photopolymerization of a layer of resin with ultraviolet light at micro-scale resolution, allowing the company to achieve ultra-high accuracy precision and resolution that cannot be achieved with other technologies.

The new process can help with creating prototypes for micro-scale parts. The technology is particularly useful for manufacturing aids, fixtures, molding and casting tools, cavities, component parts, spare parts, as well as personalized parts.

Prepared to dive into the world of futuristic technology? Attend INNOTECH 2023, the international convention and exhibition for cyber, HLS and innovation at Expo, Tel Aviv, on March 29th-30th

Interested in sponsoring / a display booth at the 2023 INNOTECH exhibition? Click here for details!