This post is also available in:

עברית (Hebrew)

עברית (Hebrew)

The development of a new class of materials is opening up endless opportunities in fields such as mechanics, electronics, heat transfer, chemistry, optics, etc. FVMat (Filled Void Materials), an innovative startup participating at the iHLS Security Accelerator, has been revolutionizing the realm of materials by the design, simulation and production of novel meta-materials. This ground-breaking development has created a unique playground for the design, simulation and fabrication of novel materials, products, and devices in a wide array of fields.

Meta-Materials are materials with an engineered, artificial micro-structure that is designed to produce desired physical and mechanical properties.

FVMat has pioneered a new concept of meta-materials which not only enables control over the material’s properties but also changes the materials’ properties in accordance with environmental conditions.

Their concept enables the production of materials with extraordinary properties, e.g. regarding controllable density, stiffness, heat transfer and expansion, permeability, dialectic and electrical coefficients, reaction to the presence of various chemicals, etc.

The company has developed a code that builds computerized models of the micro-structure of material. The code enables the testing of the material’s properties and an optimization process that yields the required properties.

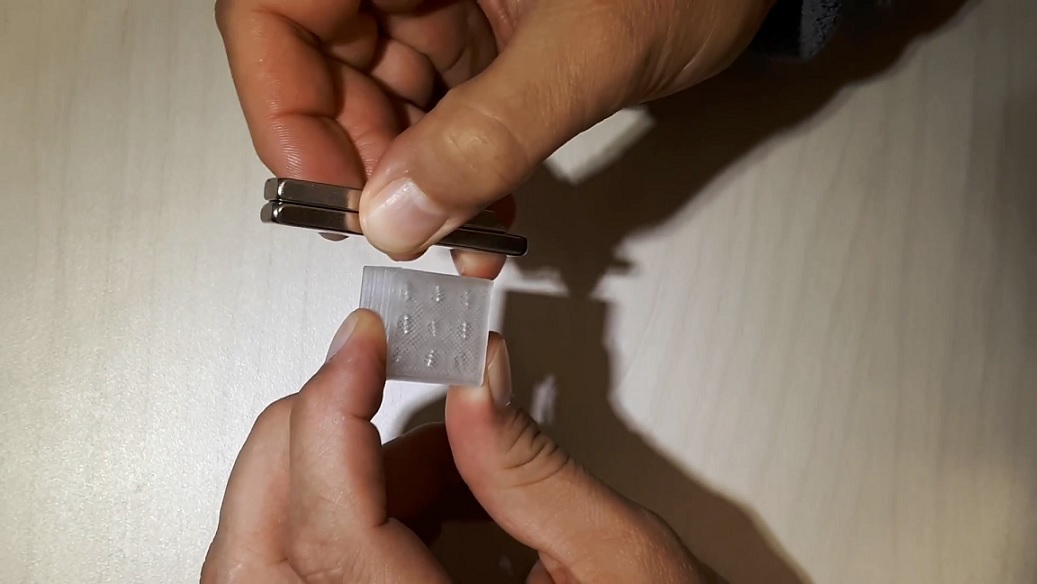

A prototype has been built, demonstrating a specific case of a micro-structure with magnetic particles moving inside the voids. This served as a proof of concept which led to the granting of a PCT patent to the company.

The micro-structure of the new meta-material is composed of three main components:

- Matrix – the main substance from which the material is made of.

- Void inside the matrix – with a controllable void shape and size.

- Substance – particles, fluids, powders, gases, or any combination of the previous residing inside the void.

By controlling these building blocks, the technology enables design and manufacturing of materials with groundbreaking properties never imagined before.

Utilizing recent advances in 3D printing has allowed the company to turn this abstract concept into feasible and achievable goal.

The technology has endless applications. These include UAVs, Airplane & Automotive components, safety catches and mechanisms, electronic components, antennas, radars, controllable heat transfer, self-lubricating materials, damage indicating materials, acoustic controlled materials, and more.

One of the use cases the developers have in mind is enhancing vehicle, tank or even building protection: Once a sign is received from a radar, electro-magnetic fields are activated, initiating the movement of the particles in the protection material, adding active or non-active resistance against shells and other threats.

![]()

The young company was founded at the beginning of 2019 by Jacob Klepach and Doron Klepach. Jacob, CFO & co-founder, who holds a B.Sc in Mechanical Engineering from the Technion, specializing in materials, has vast experience with materials and industry. He has been involved in manufacturing, acquisition and testing of materials and metals, and leads business development and finance management activities.

His son, Doron, CTO & co-founder, holds a PhD in Computational Mechanics from UC Berkeley and B.Sc. & M.Sc. in Mechanical Eng. from the Technion. A lecturer in Tel Aviv University, who had served as a scientist in a startup developing software for the characterization of composite materials.

The two were joined by Ilya Beletsky, Chief Scientist, who holds a M.Sc. in Mechanical Eng. from the Technion, and a B.A. in Physics, a B.A. in Computer Science, and a B.Sc. in Aerospace Engineering from the Technion.

As Doron told iHLS, the company strives to advance its idea and turn it into a reality by supplying engineers with tools for the development and manufacturing of the materials and eventually create new components and installations that have never existed before.

The company has already been in contact with various defense and commercial companies and is surely on its way to turn theory into practice and revolutionize industry.