This post is also available in:

עברית (Hebrew)

עברית (Hebrew)

A new sensor based on graphene might revolutionize the biosensing and defense industries. The multi-modal super sensor design is made of a single layer of graphene. Grolltex’s sensor was recently granted a patent by the United States Patent and Trademark Office. The company claims it is the smallest, most sensitive sensor in the world.

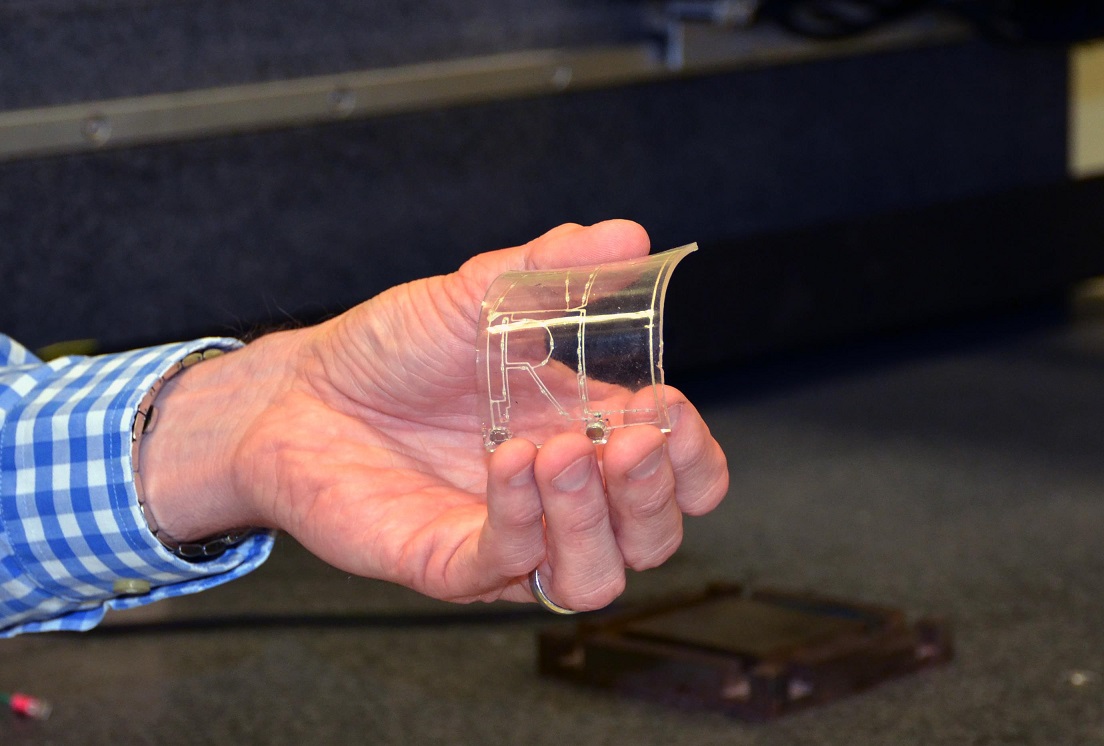

Graphene sensors are showing great potential with a range of abilities. The patent covered sensor has little to no signal drift when exposed to extreme levels of heat and can be discreetly layered into the skins of airplanes and other high-stress vehicles, or even buildings and bridges. This means the sensor can be used to measure and detect micro stress in real time at levels not currently possible with our latest sensing technologies.

Graphene is likely to be a dominant material across all industries. Even wearables are incorporating the use of this material, with the first graphene running shoes slated to hit the market next year.

“Our single atom thick sensor design, in the strain sensor configuration, is so sensitive that it captures a robust and repeatable signal on the contractility strength of individual cardiomyocytes, or heart cells, as they beat,” said Jeff Draa, CEO of Grolltex. “This can be a holy grail for fields such as cardiotoxicity testing as it has the capacity to be a significant time and money saver in the new drug testing approval process,” he added.

It is the world’s very first 2D material and has captured the attention of researchers, scientists, and industries across the world. Not only is it the thinnest material possible, but it is also transparent. Both are surprising features for an incredibly flexible material that is 200 times stronger than steel, according to thebossmagazine.com.

According to grolltex.com, the Graphene applications get closer to their desired use in wearable electronics and in biological and disposable sensors. The ultrathin graphene could be manipulated to wrap around a sensor which is usually made on a more rigid 2D substrate. The graphene can do this all the while providing electrical measurements or enhancing optical signals—in 3D. This also increases the surface area for the sensors, making graphene more seamless around the sensor. For wearable electronics, by creating more precise creases, a band gap is created in the graphene. This can help with making transistors more flexible and compact.