This post is also available in:

עברית (Hebrew)

עברית (Hebrew)

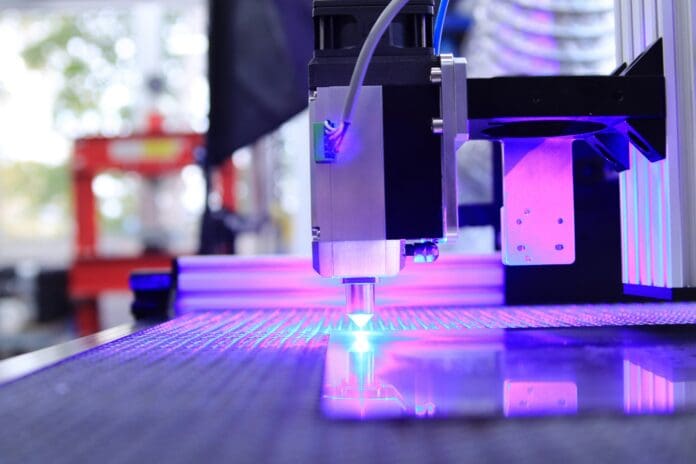

The U.S. Army is shifting its approach to battlefield logistics by expanding the use of 3D printing for rapid equipment repair. Under a new policy, field commanders now have the authority to approve the use of 3D-printed replacement parts without requiring clearance from senior leadership outside the combat zone.

The change, announced by Army Secretary Daniel Driscoll, reflects a broader push to integrate additive manufacturing into frontline operations, enabling faster repair of equipment. By giving local decision-makers control over component repairs, the Army aims to minimize downtime and keep critical systems operational, according to Breaking Defense.

Until now, even simple 3D-printed parts had to be reviewed and approved through centralized processes. This created delays, especially in forward-deployed environments. The updated policy allows officers on the ground to judge whether a printed part is sufficient for operational use, based on their assessment of functionality and risk.

Driscoll noted that many howitzers have remained out of service due to missing or damaged parts that are already available as 3D print files. The new directive encourages field units to produce and deploy these parts directly, accelerating the maintenance cycle and reducing dependency on traditional supply chains.

Additive manufacturing has already proven useful in small-scale applications, with several thousand parts produced to date. Some replacements, according to Army officials, have even outperformed the original components.

Looking ahead, the military sees additive manufacturing as particularly valuable in geographically challenging regions like the Indo-Pacific, where long resupply routes present logistical obstacles. Localized production could be key in sustaining operations in the event of a high-intensity conflict, particularly as concerns about a potential confrontation with China continue to shape U.S. defense planning.

With expectations of increased investment in fiscal year 2027, additive manufacturing is poised to become a core capability—offering not just faster repairs, but more resilient, decentralized supply networks in future operations.