This post is also available in:

עברית (Hebrew)

עברית (Hebrew)

A new research facility in Illinois is set to transform how the U.S. military produces critical components for ground vehicles, harnessing large-scale metal additive manufacturing to speed up part production and reduce dependence on traditional supply chains.

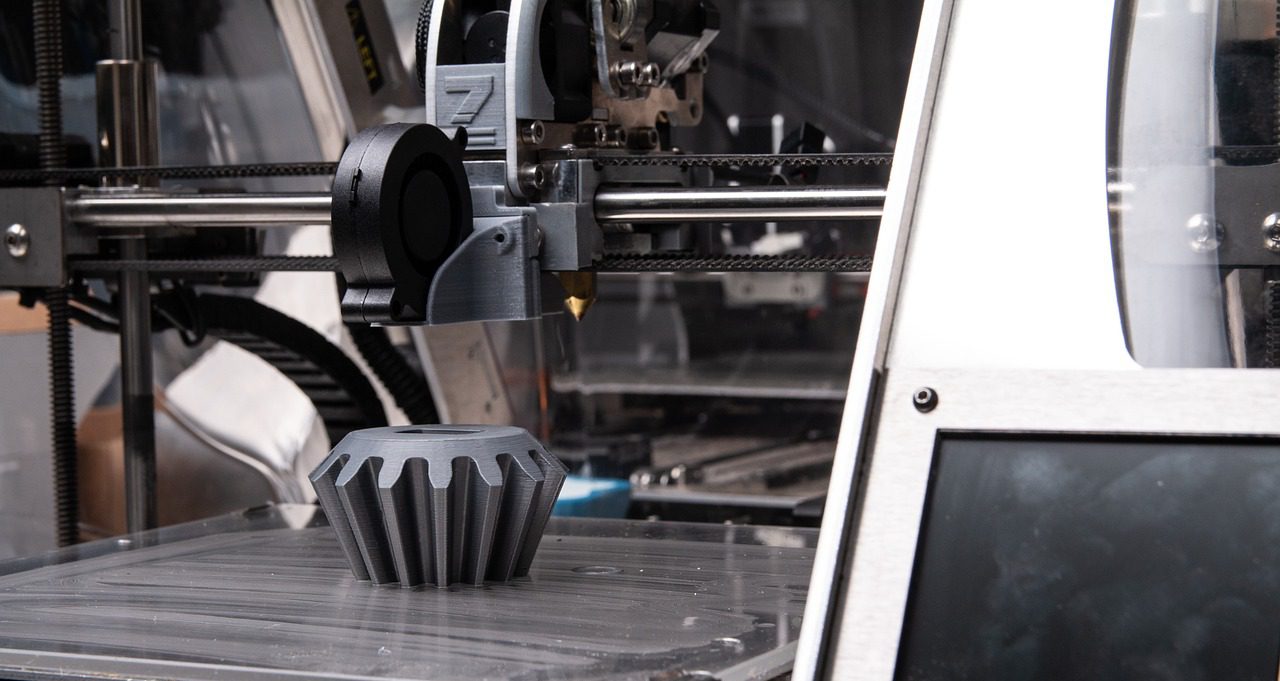

Backed by $9 million in funding—including $8.15 million from the U.S. Department of Defense—the lab, based at the Grainger College of Engineering at the University of Illinois Urbana-Champaign, will focus exclusively on advanced 3D printing for large metal parts. This marks the first university research center dedicated specifically to metal additive manufacturing at this scale, according to the Press Release.

The lab’s mission is to develop next-generation processes and tools for fabricating essential vehicle components directly from digital designs. Additive manufacturing offers a level of flexibility and speed that conventional methods can’t match. This capability could significantly reduce the time it takes to deliver replacement parts.

Beyond faster production, the technology allows for real-time adaptation. A single machine can make many different parts, a feature that could prove vital for dynamic battlefield logistics. The lab will also conduct foundational research into material performance and part durability, ensuring that the printed components meet military standards.

The timing is strategic. Earlier this year, U.S. Army units began field-testing 3D printing for rapid repair of damaged vehicles—right at the point of need. The new facility is expected to build on those efforts by refining the science behind large-scale metal printing and ensuring the repeatability and reliability of parts produced under combat conditions.

This initiative is part of a broader military push to modernize logistics and enhance operational readiness. By investing in advanced manufacturing research, the defense sector aims to reduce equipment downtime, improve battlefield resilience, and respond faster to evolving mission requirements.