This post is also available in:

עברית (Hebrew)

עברית (Hebrew)

Researchers at EPFL have developed a novel 3D printing process that allows for the creation of dense and complex metal and ceramic architectures, opening new possibilities for applications in energy, biomedicine, and sensing.

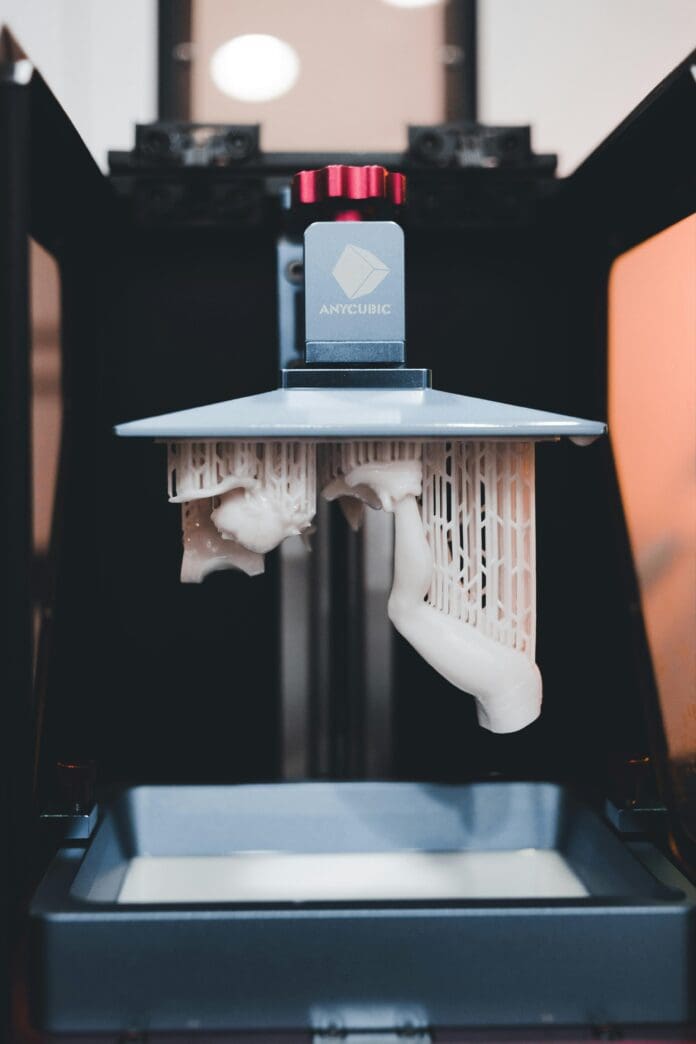

The technique departs from traditional metal 3D printing methods, which typically rely on resin materials infused with metal precursors. Instead, the EPFL team begins by printing a scaffold using a hydrogel—a water-based, flexible material. This scaffold acts as a “blank” structure that is later infused with metal salts.

Once the hydrogel is saturated with the metal solution, a chemical reaction converts the salts into nanoparticles that embed throughout the material. Repeating this infusion process increases the metal content without compromising the structural integrity. The final stage involves heat treatment, which converts the high-metal-content gel into dense ceramic or metal.

One of the main advantages of this method is the mechanical performance of the resulting materials. According to the press release, structures produced using this process can withstand up to 20 times more pressure compared to those created with earlier hydrogel-based approaches. In addition, the process achieves minimal shrinkage—about 20%, compared to 60–90% seen in previous methods—making it suitable for applications where precision and durability are essential.

To demonstrate the method’s versatility, the researchers fabricated complex gyroid structures out of iron, silver, and copper. These intricate geometries, known for their strength and low weight, were tested using a universal testing machine to evaluate their resilience under pressure.

Because the material loading is performed after the 3D printing step, this approach allows greater flexibility in choosing the material composition later in the manufacturing process. The method is considered especially promising for producing components that require both structural complexity and high material performance—such as catalytic surfaces in energy systems, biomedical implants, or miniaturized heat exchangers.

The results, published in Advanced Materials, show that this infusion-precipitation strategy can achieve ceramic and metallic parts with over 80% density, while maintaining their intricate shapes. This approach could offer a scalable and cost-effective manufacturing route.