This post is also available in:

עברית (Hebrew)

עברית (Hebrew)

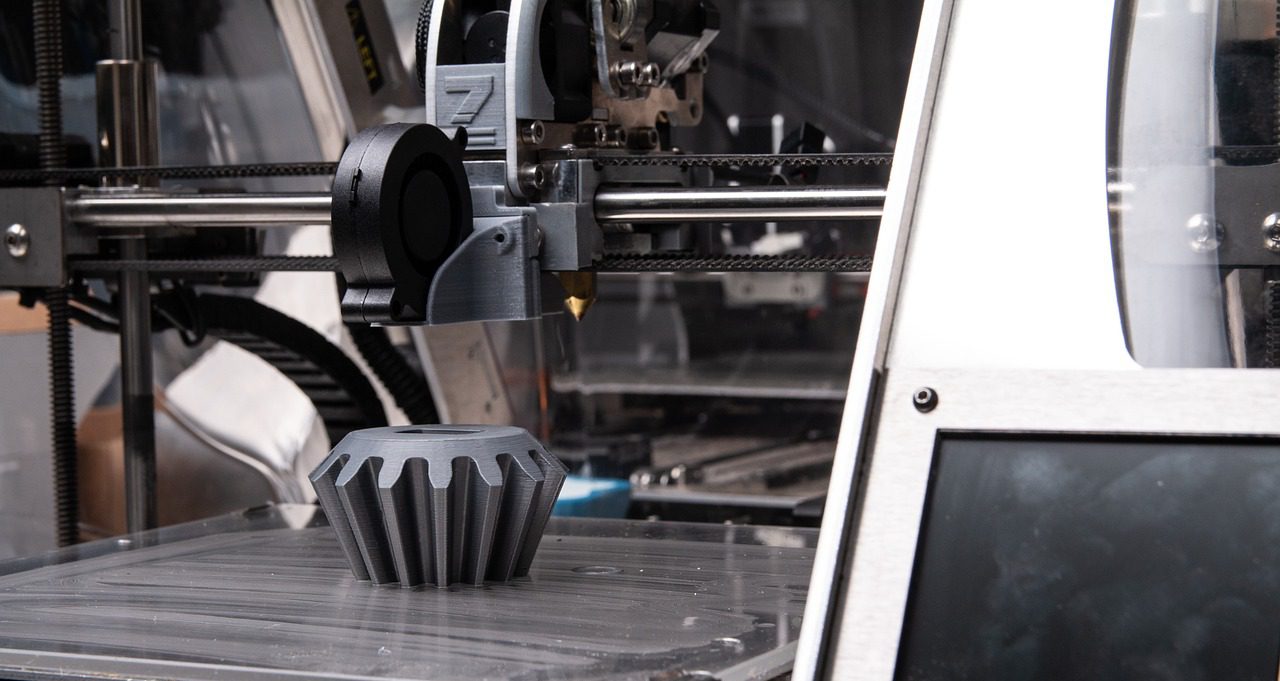

Royal Melbourne Institute of Technology (RMIT) Researchers have developed a titanium alloy specifically designed for 3D printing, addressing two long-standing challenges: high material costs and inconsistent mechanical properties. The new formulation is 29% cheaper to produce than standard titanium alloys like Ti-6Al-4V, a commonly used material in aerospace and medical applications.

The breakthrough comes from replacing vanadium—a key but increasingly expensive element in traditional titanium alloys—with more abundant, lower-cost alternatives. This adjustment not only reduces production costs but also improves the material’s overall performance.

According to the press release, One of the main technical advancements lies in the alloy’s grain structure. Unlike typical 3D-printed titanium, which often forms columnar microstructures that can lead to uneven strength and reliability, the new alloy features a uniform grain pattern, resulting in stronger and more ductile printed parts.

Performance testing has shown that the alloy meets or exceeds the mechanical properties of current materials, while also being better suited to additive manufacturing processes. According to the researchers, this marks a significant shift from modifying existing alloys to designing new ones specifically for 3D printing—a key step in unlocking the full potential of additive manufacturing.

While the exact composition of the alloy remains undisclosed due to commercial considerations, the research team has confirmed that samples were successfully produced and tested.

The team is now seeking industry partners to support further development and commercialization. By involving companies from across the supply chain, the goal is to move the alloy from lab testing to industrial-scale use.

This research aligns with wider efforts to optimize 3D-printed metals. These developments reflect growing momentum in the push to develop purpose-built materials for additive manufacturing, potentially reshaping how high-performance parts are designed and produced across industries.