This post is also available in:

עברית (Hebrew)

עברית (Hebrew)

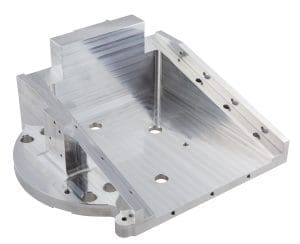

During the recent year, an experienced Israeli industrial company has demonstrated momentum and innovation after it had accomplished complex objectives in a challenging period of time. Metalicone Technologies is at the forefront of global technology in high-precision Machinery and mechanical assemblies. The company manufactures top-quality products for a wide range of industries, including Aerospace, Trains, Semiconductor, Digital Printing, Machine tools, Forging Dies for jet engine blades, Railway items, Medical and more.

Founded in Israel in 1999 by industrialist and Israel Prize winner, Mr. Stef Wertheimer, and currently owned by the Wertheimer family, the company has some 120 employees in Israel, at the Lavon Industrial Park, and another 30 employees working for its subsidiary in Germany.

During the last year, the company has been going through a substantial transformation after defeating many challenges in an exceptional way, some resulting from the global COVID-19 pandemic and others – from the dynamics and changes in the various markets it has been active in.

As a result of new measures initiated by the CEO Ram Bar Gil, who had assumed office in October 2019, the company has succeeded in recruiting new customers within a short period of time, enter new fields and activities, experiencing a vast accumulation of orders while continuing to expand the links with customers chosen as its strategic partners. Bar Gil, who had served as the company’s CFO for the last nine years, has extensive international experience in the machinery industry, and he is an accountant.

Metalicone intends to advance its position in the value chain from a company that supplies solutions in accordance with the customer’s sketches (BTP – Build to Print) to a company that provides a complete response of ensemble manufacturing in accordance with the customer’s demands (BTS- Build to Spec), The company has proven capabilities in joining the process right from the product development phase, in collaboration with the customer, and the ability to progress from prototype development to serial production. The company’s vast experience and wide knowledge allow it to manufacture components at the highest level of precision, and its five quality standards have awarded it with the Standards Institution of Israel’s platinum mark.

Four divisions currently operating in Metalicone manufacture a wide array of components and ensembles:

- Aerospace – the manufacture of parts for commercial aircraft, jet engine blades forging molds, etc.

- Semiconductor – Wafers, Chucks, kits, End effectors, adaptors, Sub-assemblies and additional parts in accordance with micron-level geometric tolerancing demands.

- Machinery – manufacture of parts and Sub-assemblies for Machine tools, spindles, and most recently also for the railway sector.

- Printing – manufacture of parts and Sub-assemblies for giant companies in the printing industry.

Metalicone’s subsidiary in Germany supplies a response to the local machinery industry, constituting the Israeli Headquarters’ front entrance to Europe.

Metalicone’s marketing strategy has been overhauled recently too, in a move led by Yanir Sharon, VP Marketing and Sales. Following this move, each division currently has some 3-4 leading customers constituting the majority of the business operations of that division, alongside new customers identified by the company as having the potential for extensive growth.

Sharon said: “A new policy for strategic customers has been established – a few central, old and new customers with high business potential, who benefit from very short response time (SLA). A dedicated NPI – New Product Integration department is currently established by the company’s CTO, Michael Shitenburg, in order to provide rapid response to the company’s strategic customers. Shitenburg is one of Israel’s leading professionals in the Machinery field, with over 20 years of experience in Metalicone.”

Metalicone’s seasoned professionals and experts work hand in hand with the customer from the development and prototype production stages throughout the testings and finally during the serial manufacturing. These results have been reflected by the close, long-standing relations with the company’s satisfied customers.

![]()

Among Metalicone’s customers (Tier 1 & Tier 2) are the world’s leading companies, including, Boeing, Airbus, Gulfstream, Applied Materials, Jabil, Sanmina, Flex, Pratt and Whitney, ThyssenKrupp, HP Indigo, KLA, Camtek, Highcon Landa, Rolls Royce, and more.

Metalicone aims at positioning itself as a leading, world-renowned company supplying precision parts of the highest quality. According to Yanir Sharon, the company has many plans for the future, and its vision calls for advancing its position along the value chain and providing a complete, focused response to its customers. On the agenda is the opening of a cleanroom that would provide response to the growing needs of the optics and semiconductor industries.

Most recently, the company has established Metalicone Academy – a unique instruction framework by lecturers from the company as well as from other sources, designed for employees and executives in order to provoke brainstorming in various fields, develop innovation, and cope with future challenges.